What is SC bocad Offshore?

SC bocad Offshore is a powerful, industry‑proven BIM solution tailored for the conceptual and detailed design of complex offshore and marine steel structures. It provides a range of specific tools for sustainable structural‑steel conceptual and detailed design up to fabrication and construction of offshore and marine projects such as wellhead and production‑platform topsides, jackets, spars, semi‑submersibles, tension‑leg platforms (TLP), jack‑up rigs, floating production storage and offloading (FPSO) vessels, and offshore wind farms.

With its unique ability to enable 3D modelling directly in General Arrangement drawings, SC bocad Offshore saves countless hours on revisions and guarantees that your design drawings are always current. It also includes Weight Control Reports, Profile Cutting Plans, automatic weld‑marking, rolled‑plate unfolding, and 3D pipe‑profiling—streamlining every stage from initial concept to final construction.

SC bocad Offshore ensures real‑time accuracy and full compliance with API, DNV, ISO, and AWS standards, making it the go‑to solution for engineers and designers worldwide.

- Rule‑Driven Code Compliance

- Automated Fabrication Deliverables

- Clash Detection & Resolution

- Integrated Fatigue & Dynamic Analysis

- Weight Control & Material Optimization

- Sustainable Conceptual & Detailed Design

- Global Standard for Marine projects

- 24/7 Customer support

Power your offshore projects with bocad offshore — precision detailing for oil, gas & marine structures

Why SC bocad Offshore Leads the Way in Offshore Structural Design & Detailing

When it comes to offshore structural steel design, SC bocad Offshore stands out as the go‑to BIM extension—delivering accuracy, efficiency, and full compliance from concept all the way to shop‑floor fabrication. Here’s why top EPCs and detailing houses choose it:

Key Advantages of SC bocad Offshore

End‑to‑End Offshore Workflows

Conceptual modeling through detailed fabrication and construction deliverables, including jackets, spars, TLPs, FPSOs and wind‑farm foundations.

Parametric 3D Modeling Templates

Generate wellhead and production‑platform topsides, jackets, semi‑submersibles and more in minutes with customizable, project‑specific templates

Real‑Time GA Drawing Generation

Unique ability to create up‑to‑date general arrangement drawings—cut revision time drastically and eliminate drawing-version mismatches.

Automated Fabrication Reports

One‑click exports for weight‑control summaries, profile‑cutting plans, automatic weld‑marking, rolled‑plate unfolding and 3D pipe‑profiling

Built‑In Code‑Driven Checks

Auto‑apply API, DNV, ISO and AWS standards to members, connections and welding inspections—no manual recalculations

Advanced Clash Detection & Multi‑Discipline Interop

Embedded collision checks, compare‑and‑update with plant software, and IFC‑based BIM workflows for steel, pipe and plant integration

Weight Control & Material Optimization

Live material‑takeoff and nesting reports minimize waste, drive sustainable design, and reduce procurement costs

Advanced Weld Preparation & Inspection Reporting

Advanced weld‑preparation and inspection reporting automates bevel detailing, AWS‑compliant NDT mapping and weld‑map exports for fabrication accuracy.

Dedicated Offshore Support

Expert Sravani Infotech team delivers hands‑on training, custom scripting and rapid after‑sales service for smooth product delivery.

Maximize Offshore Efficiency – Deliver robust, accurate detailing with bocad offshore

Project Modules in SC bocad Offshore

Create peaks, cages, cross‑arms and main body structures.

Parametric Grid Setup: Define tower footprint, leg spacing and height increments with live previews.

Base‑Plate & Anchor Modeling: Automatically place and size base‐plates and anchor‐bolt patterns per project specs.

Composite Section Support: Mix angular, tubular or cold‑formed profiles within the same body segment.

Real‑Time Height Adjustment: Drag handles or enter values to instantly update overall tower height and segment ratios.

Add stud‑body and leg extensions for varied tower heights.

Variable Stub Lengths: Apply different stub‑body and leg‑extension lengths per corner or side.

Transition Elements: Insert tapered or stepped extension sections to smoothly bridge body segments.

Automated Member Re‑mapping: Re‑assign cross‑bracing and diagonal patterns when extensions change.

Stub‑Bolt Integration: Automatically add and dimension the bolted connection between extension and main body.

Generate transversal/longitudinal faces and hips on preset grids.

Custom View Templates: Save and re‑apply favorite face/plan layouts (e.g. front elevation, side elevation).

Automatic Dimensioning: Populate key dimensions (member lengths, angles, hole‑to‑hole distances) on each view.

Isometric Export: One‑click to generate shaded or wireframe isometric views for presentations or reports.

Layer‑Based Filtering: Show/hide elements (bolts, welds, accessories) per view with dedicated layers.

Star‑leg, double‑star legs; butt/lapped joints; user‑defined angle creation.

End‑Preparation Types: Choose from straight‑cut, chamfered or slotted ends for each profile.

Named Library Entries: Save custom templates with descriptive names for quick reuse.

Automatic Part Numbering: Assign and sequence part IDs based on template and project rules.

Multi‑Standard Support: Maintain separate template folders for different codes or client specifications.

Redundancy checks and tools for cut/back‑cut/flange‑cut and grinding.

Real‑Time Clash Alerts: Highlight conflicts as soon as profiles or connections overlap in 3D.

Severity Classification: Tag clashes by criticality (e.g. bolt interference vs. minor edge contact).

One‑Click Auto‑Resolution: Suggest and apply the appropriate cut/grind operation based on clash type.

Revision Tracking: Log each clash and its resolution method for audit and QA processes.

Cold/hot‑bend allowances, flange creation and automatic panel selection.

Material‑Specific Bend Tables: Use built‑in allowances per steel grade (e.g. A36, S355) and thickness.

Bend Radius Control: Dial in minimum/maximum radii and receive instant feedback on formability.

Panel Nesting Preview: Visually arrange panels on stock plates to check fit before nesting.

Hole‑After‑Bend Logic: Automatically schedule hole‑drilling either before or after bending per part spec.

Step‑bolts, U‑bolts, pack‑washers, anti‑climb devices and more.

Default Insertion Rules: Predefine accessory types and quantities per member or connection.

Spacing & Alignment Controls: Set custom intervals for step‑bolts or pack‑washer stacks.

Catalog Import/Export: Bring in client‑specific accessory libraries in CSV or XML format.

Accessory Reports: Generate sortable lists of all accessories with part numbers, quantities and mounting locations.

Cold/hot‑bend allowances, flange creation and automatic panel selection.

Material‑Specific Bend Tables: Use built‑in allowances per steel grade (e.g. A36, S355) and thickness.

Bend Radius Control: Dial in minimum/maximum radii and receive instant feedback on formability.

Panel Nesting Preview: Visually arrange panels on stock plates to check fit before nesting.

Hole‑After‑Bend Logic: Automatically schedule hole‑drilling either before or after bending per part spec.

Step‑bolts, U‑bolts, pack‑washers, anti‑climb devices and more.

Default Insertion Rules: Predefine accessory types and quantities per member or connection.

Spacing & Alignment Controls: Set custom intervals for step‑bolts or pack‑washer stacks.

Catalog Import/Export: Bring in client‑specific accessory libraries in CSV or XML format.

Accessory Reports: Generate sortable lists of all accessories with part numbers, quantities and mounting locations.

Benifits of SC bocad Offshore

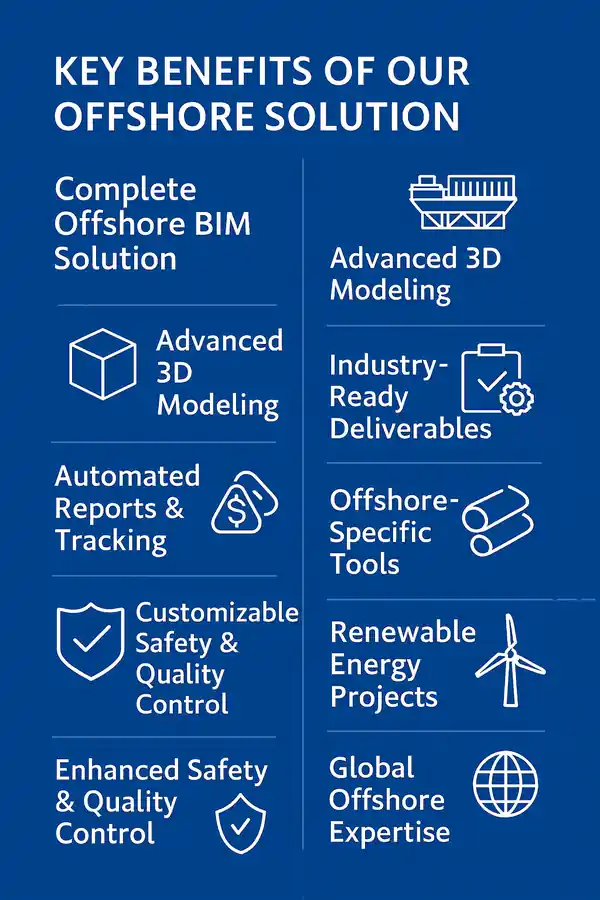

Complete Offshore BIM Solution – Purpose-built for offshore and marine structural steel design, covering conceptual design, detailing, fabrication, and construction for platforms, jackets, hulls, and wind farm structures.

Advanced 3D Modeling – User-friendly, efficient 3D modeling of complex joints and large offshore structures such as topsides, jackets, spars, semi-submersibles, TLPs, FPSOs, and substations.

Industry-Ready Deliverables – Generate accurate, high-quality general arrangement drawings, shop drawings, and assembly drawings, ensuring compliance with offshore industry standards.

Automated Reports & Tracking – Built-in weight control, welding inspection reports, weld mapping, and material summaries for accurate project monitoring.

Offshore-Specific Tools – Includes plate unfolding, profile cutting plans, weld marking, pipe profiling, and clash detection tailored to offshore steel structures.

Material & Cost Optimization – Automatic material estimation and nesting functions to minimize waste and control project budgets.

Multi-Discipline Integration – Seamless interoperability with plant design software, compare-and-update functions, and support for stress analysis.

Customizable Connection Libraries – Ready-to-use and modifiable connections for topsides, jackets, and hulls, including stiffeners, haunch joints, doubler plates, and anodes.

Pipe & Hull Detailing – Extracts bevel angles, offsets, eccentricity, and seam orientation data for 3D profiling robots and offshore manufacturing.

Enhanced Safety & Quality Control – Weld preparation compliant with AWS standards and NDT inspection-ready reports.

Ready for Renewable Energy Projects – Ideal for offshore wind farm substations and turbine support structures.

Global Offshore Expertise – Backed by a dedicated support team with years of offshore industry experience.