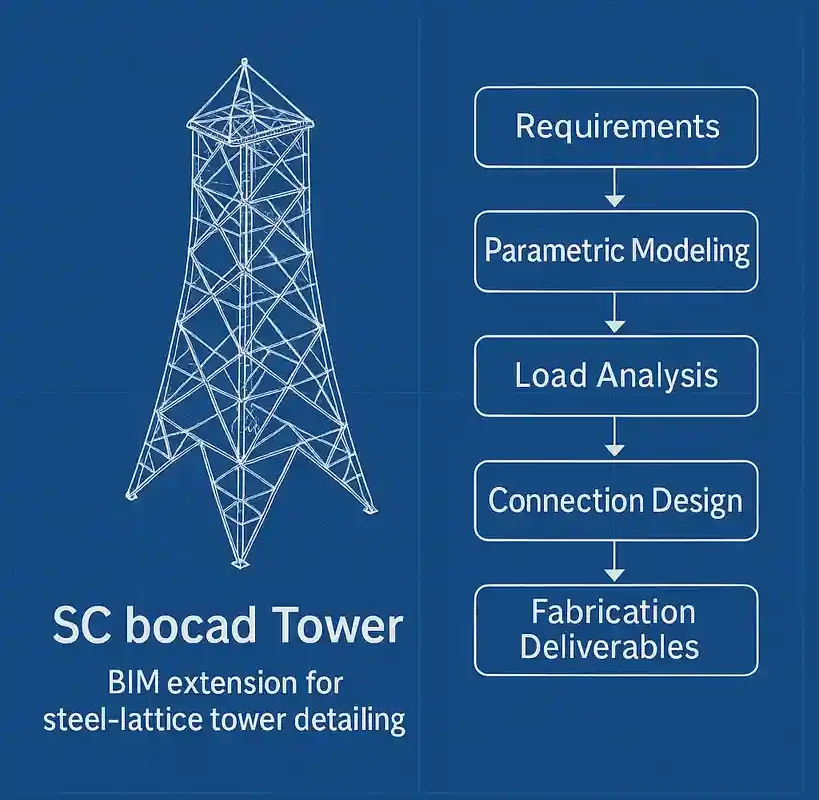

What is SC bocad Tower?

SC bocad Tower is an industry‑leading BIM extension specifically built for end‑to‑end steel‑lattice tower detailing. Sitting on top of your existing CAD or BIM platform, it empowers structural and detailing engineers to:

Parametric 3D Modelling

Quickly generate legs, bracings, cross‑arms and platforms via intuitive templates.Rule‑Driven Connection Design

Auto‑size bolts, gusset and splice plates to industry standards—no manual tweaks.Automated Fabrication Deliverables

One‑click exports of shop drawings, NC templates, bend‑reports and hole‑layout plans.Clash Detection & Resolution

Built‑in collision checks with guided cut‑and‑grind tools to fix conflicts in‑model.Material Optimization & Scalability

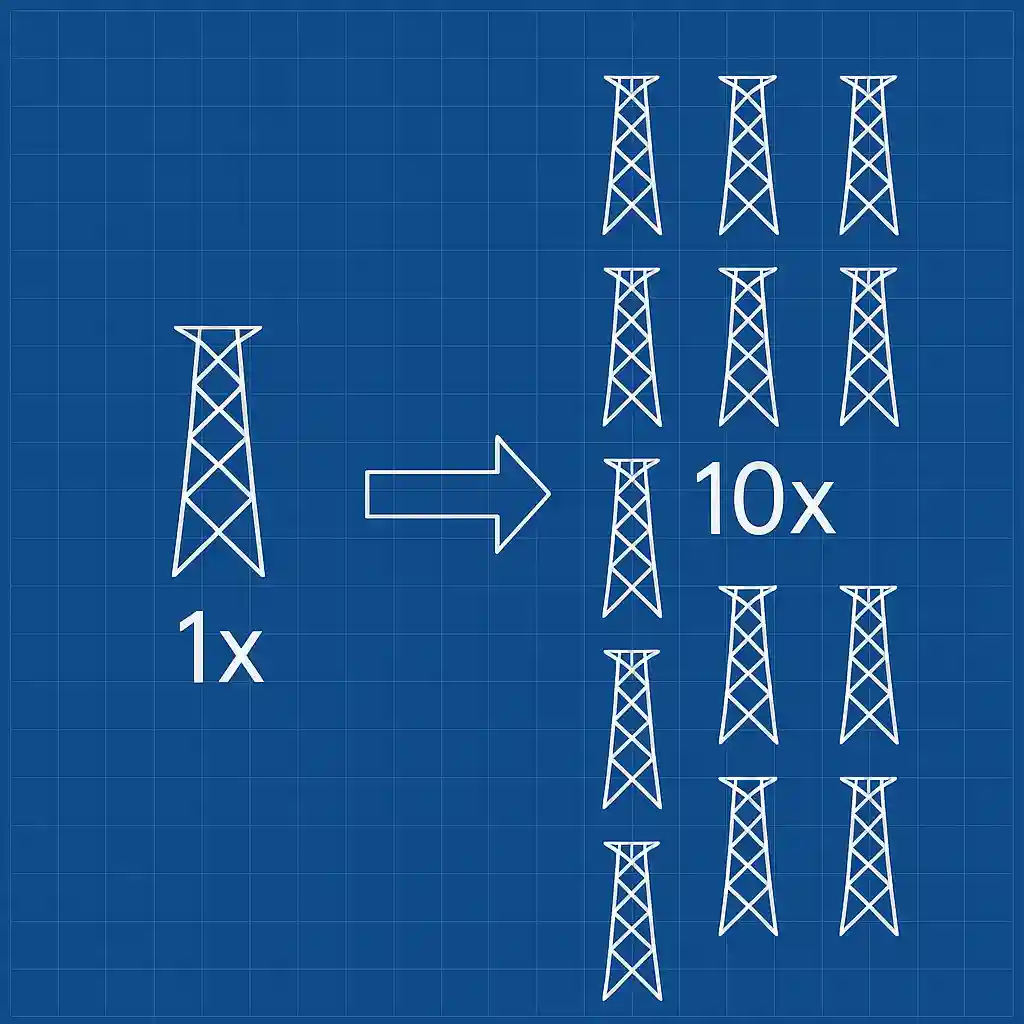

“Order‑to‑length” nesting and quantity multipliers minimize waste and scale from prototype to mass‑production.

Why SC bocad Tower-Industry leader for Tower design & Detailing

SC bocad Tower isn’t just another CAD plugin—it’s a purpose‑built BIM platform that transforms how you detail steel‑lattice towers. Here’s why leading engineering firms choose it:

Define Project Requirements

Quickly load engineering standards (wind zones, seismic categories, code parameters) and import site‑specific data.

Parametric 3D Modelling

Generate tower legs, bracings, cross‑arms and platforms via intuitive dialogs or Excel‑based templates—automatically snapping elements to grid rules.

Automated Load Analysis

Integrate wind, ice, seismic and live‑load cases. Leverage built‑in combinations per EN, AISC or IS codes to validate member sizes instantly.

Material Optimization

Leverage “order‑to‑length” profile nesting and batch quantity multipliers to scale your design from prototype to high‑volume production—minimizing waste and procurement costs.

Global Standards & Templates

Choose from a library of country‑specific templates (IEC, AISC, IS, GB) and accessory catalogs (step‑bolts, anti‑climb devices, U‑bolts) to match any project requirement.

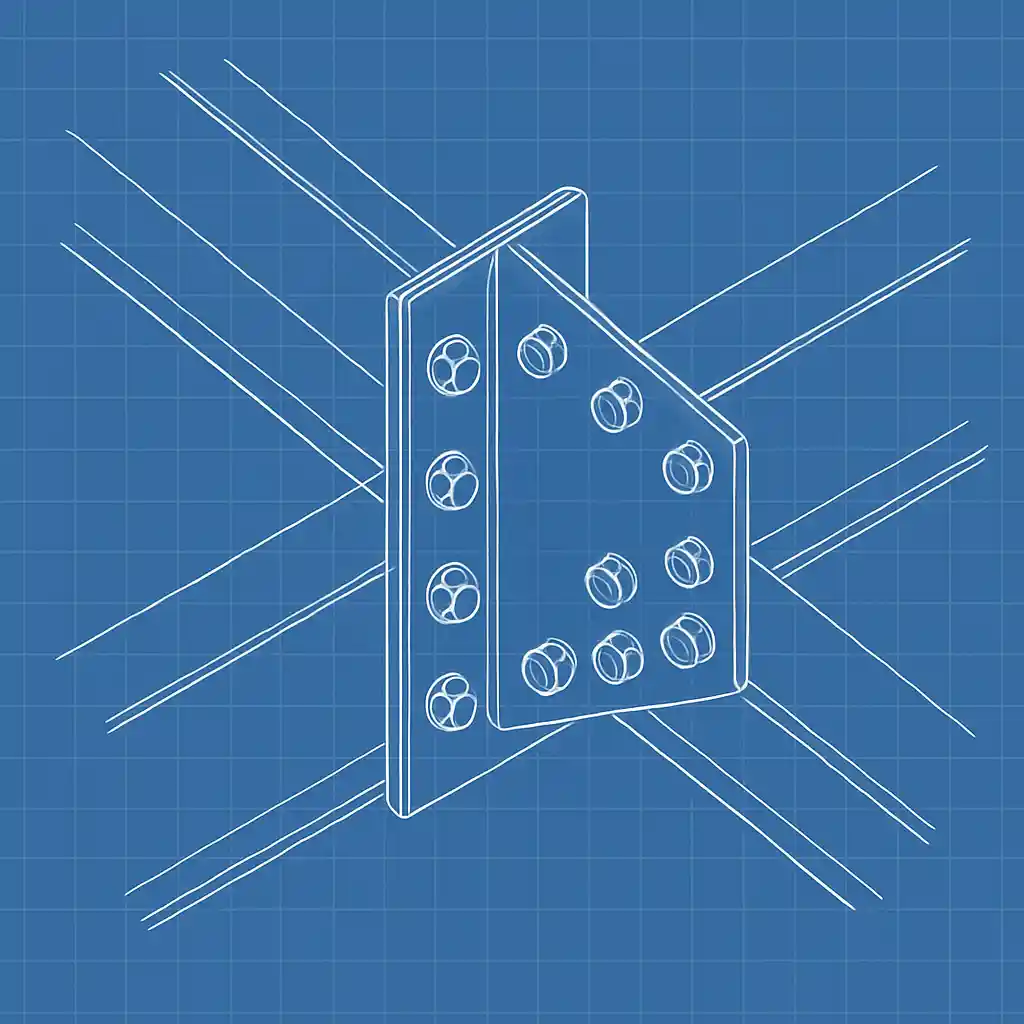

Rule‑Driven Connection Design

Auto‑size bolts, gussets and splice plates to industry tolerances. All connections follow predefined rule libraries—ensuring compliance and brand‑uniformity.

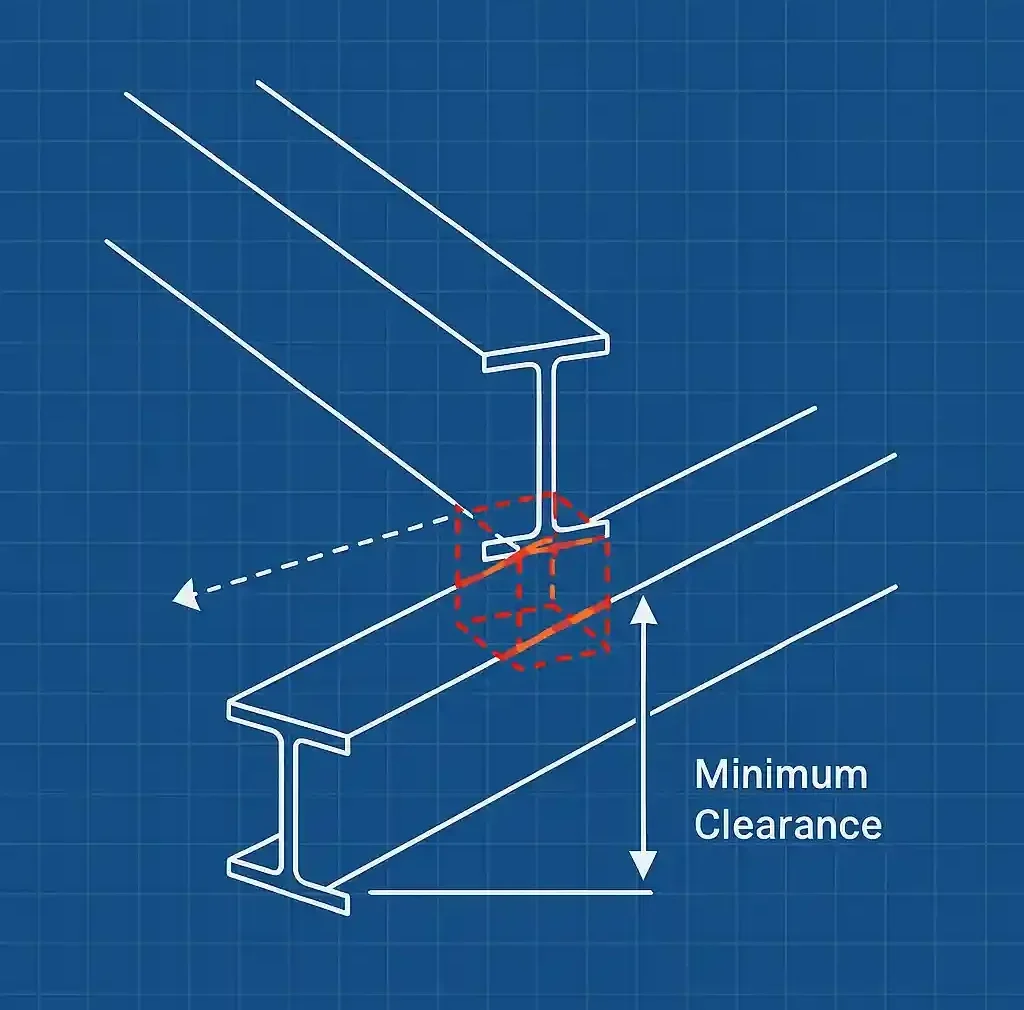

Clash Detection & Resolution

Run automatic collision checks on profiles, connections and accessories. Use guided cut‑and‑grind tools to resolve conflicts without leaving the model.

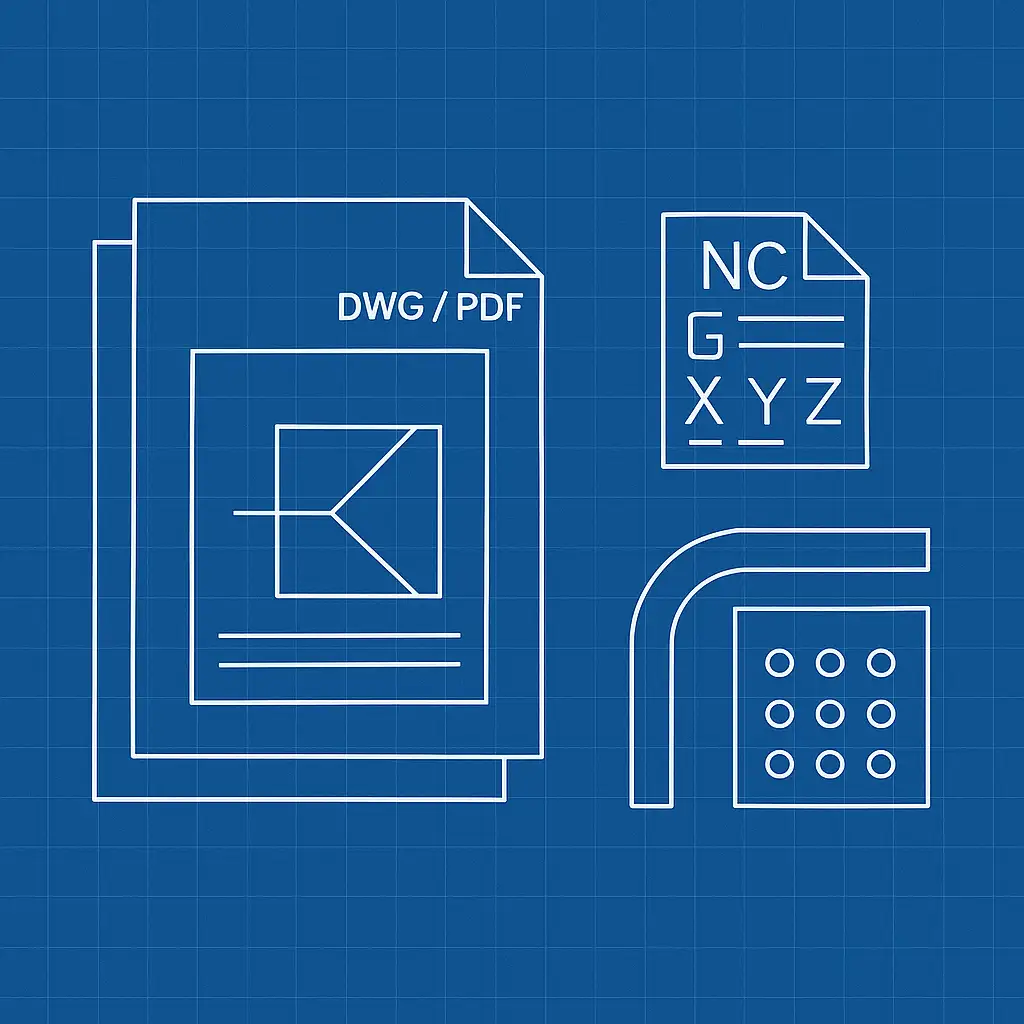

Fabrication Deliverables

One‑click exports produce NC templates, shop drawings, bend‑sequence reports, hole‑layout plans and fully annotated assembly drawings.

Seamless Data Management

Store and manage all tower‑project data (models, parts lists, revision history and reports) in one centralized BIM database, with easy revision tracking and audit trails.

Extensive Support & Updates

Benefit from Sravani Infotech dedicated support network, regular software updates and a thriving user community sharing best practices.

Design and detail towers faster with bocad tower — advanced BIM for structural towers

Key Features of SC bocad Tower

Automatic Connections

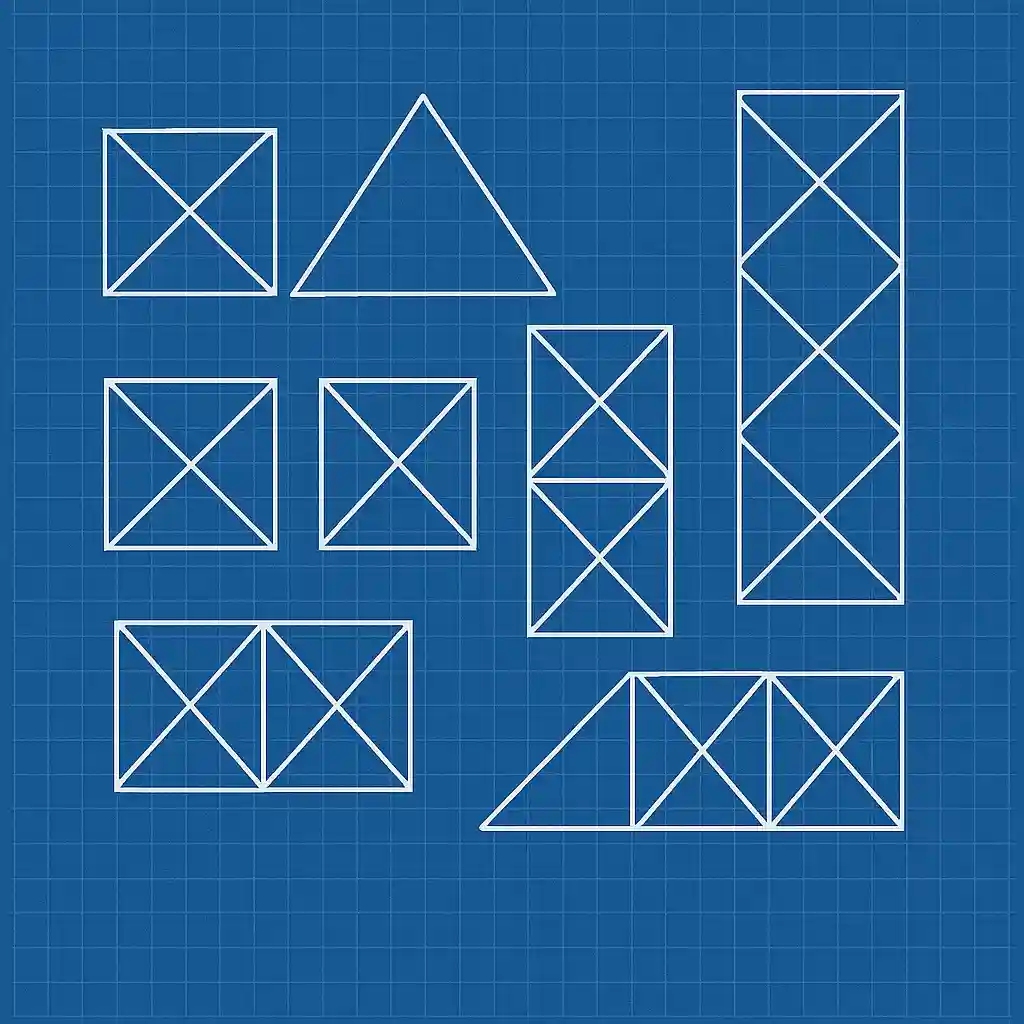

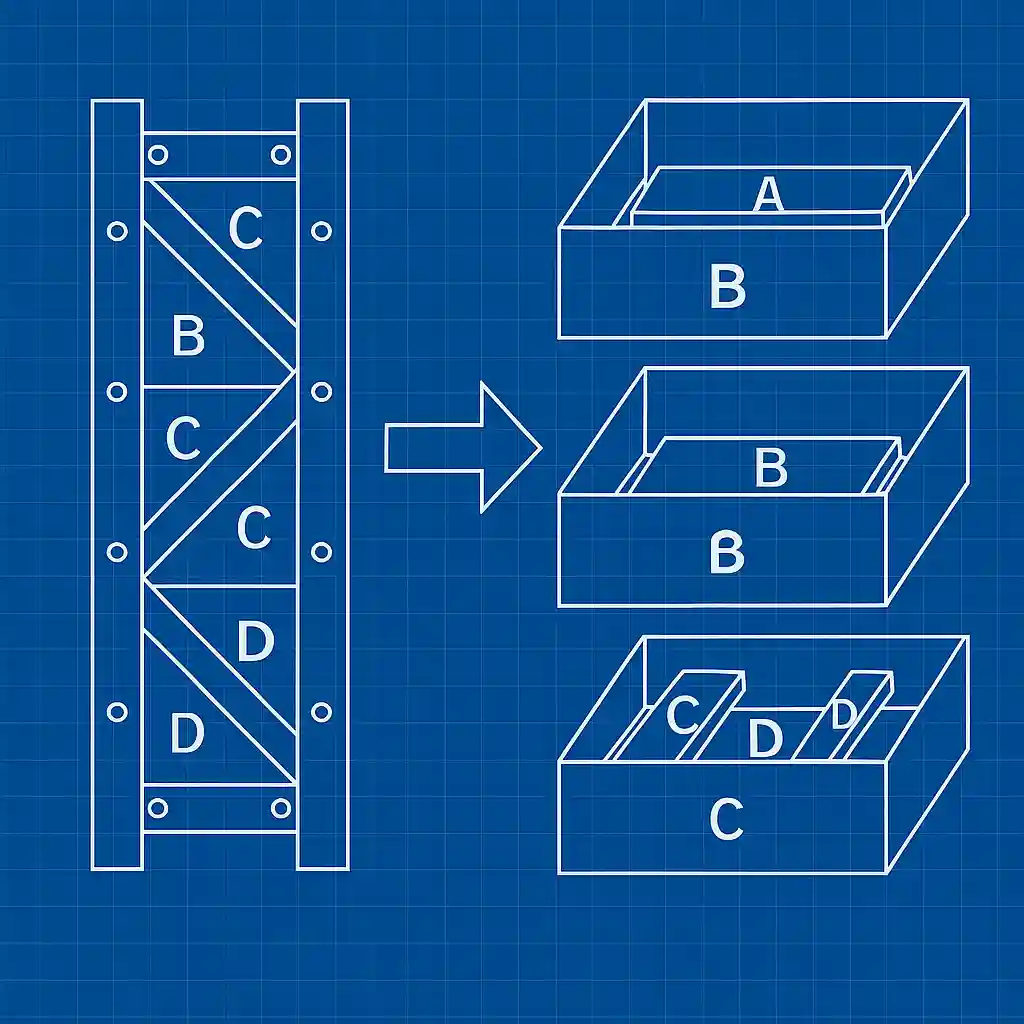

Custom Panel Libraries

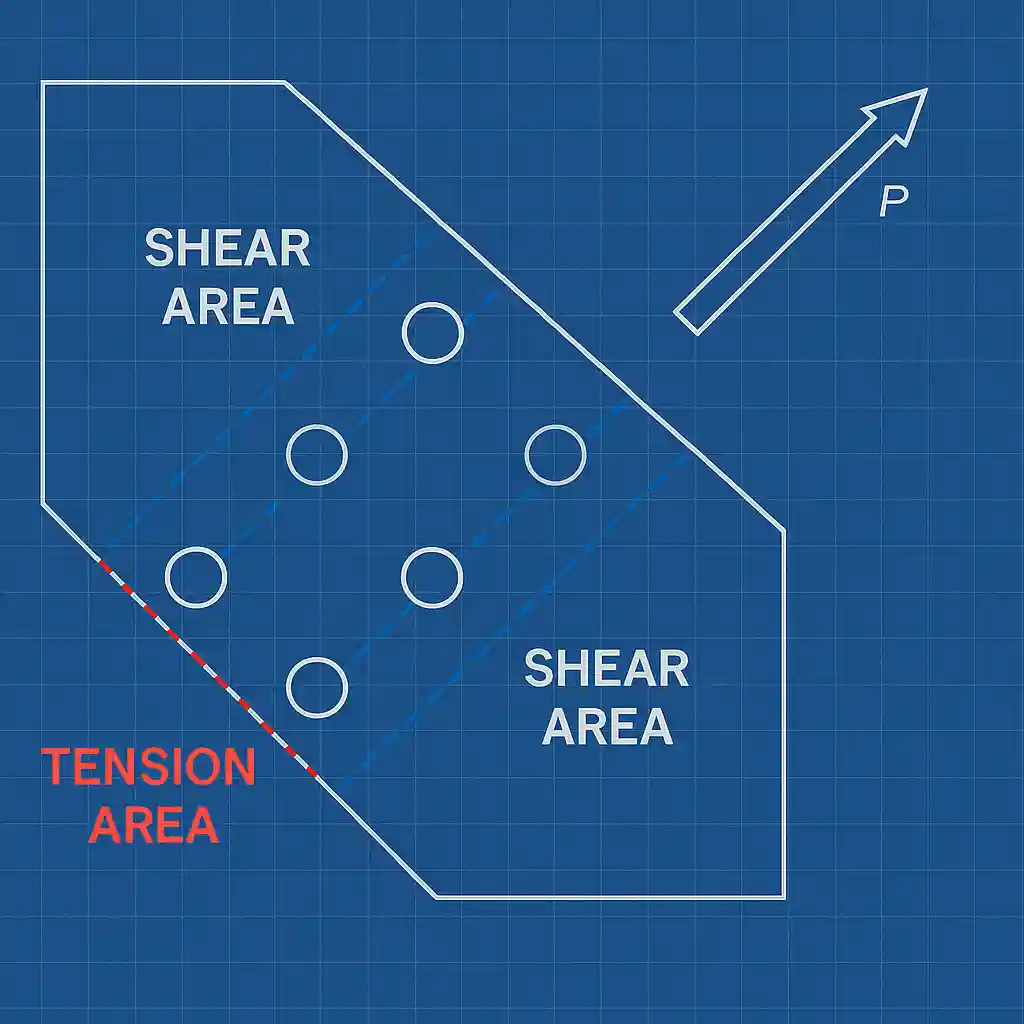

Bolt & Shear‑Edge Control

Collision & Clearance Check

Piece‑Marking & Sorting

Fabrication Deliverables

Assembly Drawings

Quantity Multiplier

Project Modules in SC bocad Tower

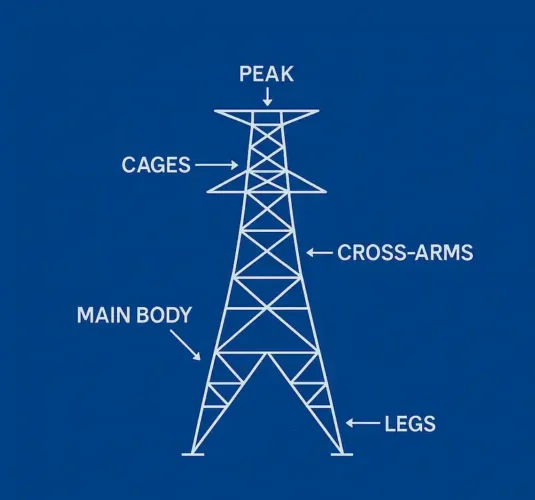

Create peaks, cages, cross‑arms and main body structures.

Parametric Grid Setup: Define tower footprint, leg spacing and height increments with live previews.

Base‑Plate & Anchor Modeling: Automatically place and size base‐plates and anchor‐bolt patterns per project specs.

Composite Section Support: Mix angular, tubular or cold‑formed profiles within the same body segment.

Real‑Time Height Adjustment: Drag handles or enter values to instantly update overall tower height and segment ratios.

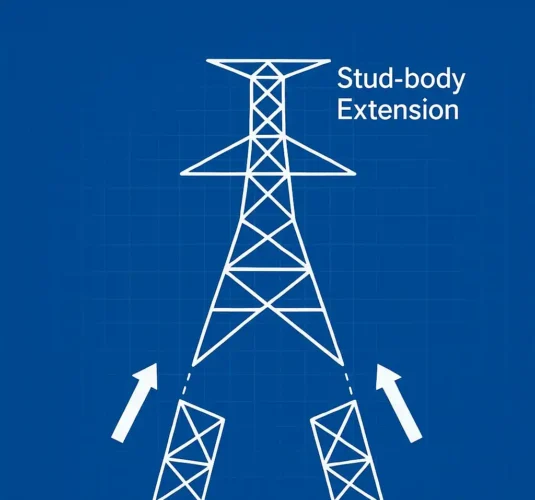

Add stud‑body and leg extensions for varied tower heights.

Variable Stub Lengths: Apply different stub‑body and leg‑extension lengths per corner or side.

Transition Elements: Insert tapered or stepped extension sections to smoothly bridge body segments.

Automated Member Re‑mapping: Re‑assign cross‑bracing and diagonal patterns when extensions change.

Stub‑Bolt Integration: Automatically add and dimension the bolted connection between extension and main body.

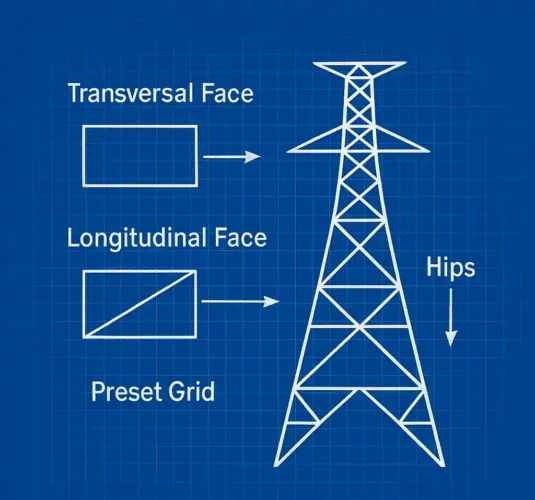

Generate transversal/longitudinal faces and hips on preset grids.

Custom View Templates: Save and re‑apply favorite face/plan layouts (e.g. front elevation, side elevation).

Automatic Dimensioning: Populate key dimensions (member lengths, angles, hole‑to‑hole distances) on each view.

Isometric Export: One‑click to generate shaded or wireframe isometric views for presentations or reports.

Layer‑Based Filtering: Show/hide elements (bolts, welds, accessories) per view with dedicated layers.

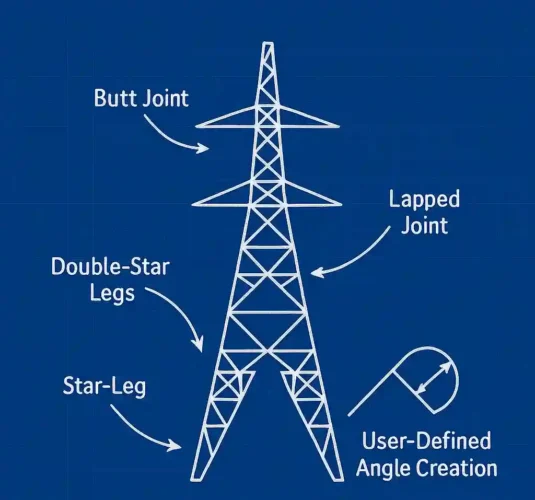

Star‑leg, double‑star legs; butt/lapped joints; user‑defined angle creation.

End‑Preparation Types: Choose from straight‑cut, chamfered or slotted ends for each profile.

Named Library Entries: Save custom templates with descriptive names for quick reuse.

Automatic Part Numbering: Assign and sequence part IDs based on template and project rules.

Multi‑Standard Support: Maintain separate template folders for different codes or client specifications.

Redundancy checks and tools for cut/back‑cut/flange‑cut and grinding.

Real‑Time Clash Alerts: Highlight conflicts as soon as profiles or connections overlap in 3D.

Severity Classification: Tag clashes by criticality (e.g. bolt interference vs. minor edge contact).

One‑Click Auto‑Resolution: Suggest and apply the appropriate cut/grind operation based on clash type.

Revision Tracking: Log each clash and its resolution method for audit and QA processes.

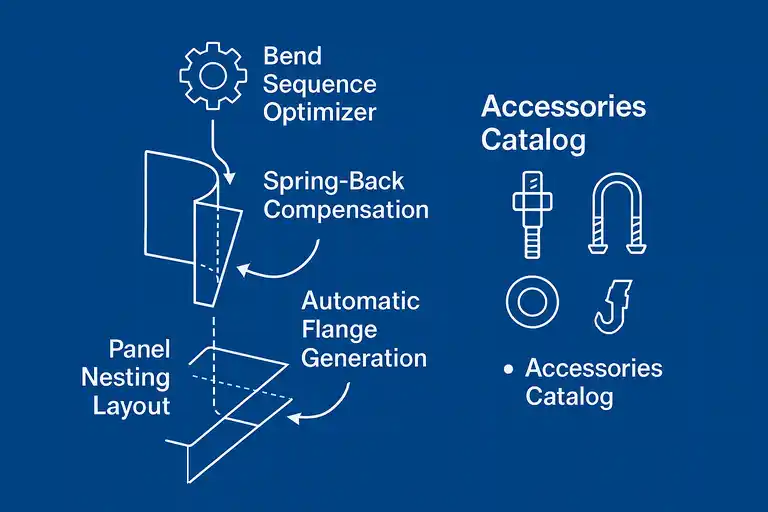

Cold/hot‑bend allowances, flange creation and automatic panel selection.

Material‑Specific Bend Tables: Use built‑in allowances per steel grade (e.g. A36, S355) and thickness.

Bend Radius Control: Dial in minimum/maximum radii and receive instant feedback on formability.

Panel Nesting Preview: Visually arrange panels on stock plates to check fit before nesting.

Hole‑After‑Bend Logic: Automatically schedule hole‑drilling either before or after bending per part spec.

Step‑bolts, U‑bolts, pack‑washers, anti‑climb devices and more.

Default Insertion Rules: Predefine accessory types and quantities per member or connection.

Spacing & Alignment Controls: Set custom intervals for step‑bolts or pack‑washer stacks.

Catalog Import/Export: Bring in client‑specific accessory libraries in CSV or XML format.

Accessory Reports: Generate sortable lists of all accessories with part numbers, quantities and mounting locations.

Benifits of SC bocad Tower

1. Eliminate Rework

BOCAD Tower embeds comprehensive, rule‑based collision and clearance checks directly into the 3D model so that any interference between profiles, bolts or brackets is detected—and automatically highlighted—before you ever cut steel. Built‑in functions (cut‑through, back‑cut, flange‑cut, grinding heel, etc.) let you resolve clashes on the fly, eliminating costly shop‑floor rework and redesign cycles.

2. Maximize Material Efficiency

Advanced nesting algorithms for both angle profiles and sheet panels ensure that every millimeter of raw material is put to use. Quantity‑multiplier features let you plan mass production runs with precise “order‑to‑length” bar nesting, while customizable profile libraries and bolt‑gage controls keep scrap rates to an absolute minimum.

3. Accelerate Production

Automated deliverables—including shop drawings, bending templates, NC files and assembly views (transversal, longitudinal, plan and hip drawings)—are generated in seconds according to tower‑industry standards. Piece‑marking, sorting and labeling by legs, diagonals or redundant members is handled automatically, cutting the traditional drafting and documentation cycle by up to 50%.

4. Ensure Consistency

A centralized library of standardized tools, joint types (butt, lapped), flange rules (open/closed) and material‑specific bending allowances guarantees uniform quality across every project. User‑defined angle creation—guided by bolt‑gage tables and shear‑distance controls—ensures that prototypes and production runs are built to the same exacting standards, every time.

Streamline tower design, fabrication workflows with bocad tower — smarter, faster, cost-effective

SC bocad-Tower Detailing Software FAQs

Common questions about modern tower modeling, detailing, and fabrication workflows.

What is SC bocad Tower used for in tower detailing?

SC bocad Tower is used for creating precise steel tower detailing, including modeling, connections, bracing, and fabrication-ready outputs for telecom and transmission structures.

Does the software support telecommunication tower modeling?

Yes, it supports end-to-end telecommunication tower modeling, including lattice masts, monopoles, and hybrid structures with automated connections.

Can SC bocad Tower generate tower fabrication drawings automatically?

Absolutely. The system produces tower fabrication drawings with plates, bolts, welds, cutting lists, and assembly details—all synced with the 3D model.

Is it suitable for lattice tower detailing software requirements?

Yes, SC bocad Tower software works as a complete lattice tower detailing software solution with parametric members, intelligent macros, and BIM-ready outputs.

Does it support transmission tower detailing workflows?

SC bocad Tower is widely used for transmission tower detailing, including angle sections, built-up members, trusses, and foundations.

Can I export NC data for tower manufacturing?

Yes, you get tower NC data export in DSTV, DXF, and other common formats that fabricators use for automated cutting and drilling machines. Sravani Infotech also an exclusive partner for

What makes it better than regular tower structure CAD software?

Unlike generic tower structure CAD software, SC bocad Tower is engineering-oriented, automates drawings, supports BOMs, and maintains full BIM consistency.

Does it support automated tower drawings for complex structures?

Yes. It provides automated tower drawings for single parts, assemblies, GA drawings, and erection maps with minimal manual editing.

Is SC bocad Tower suitable for steel tower engineering workflows?

Yes, engineers use it as a steel tower engineering software for design validation, fabrication preparation, and coordinated BIM deliverables.

Is Sravani Infotech the official partner for SC bocad Tower?

Yes, Sravani Infotech is the exclusive partner for India, Bangladesh, and Sri Lanka, providing licensing, implementation, support, and training.

SC bocad Tower: Advanced 3D Tower Detailing Software

SC bocad Tower is a specialized 3D detailing software for telecommunication and transmission towers, offering automated drawings and fab models.

Price: Contact for pricing

Price Currency: INR

Operating System: Windows 10, Windows 11

Application Category: CAD software, steel tower detailing software, engineering application

4.9

Pros

- Specialized for steel and lattice tower detailing

- Automated tower fabrication drawings and BOMs

- Supports NC and DSTV exports for workshop machines

- BIM and IFC compatible for coordinated projects

- Proven on telecom and transmission tower projects

- Handles complex geometries and large tower models

- Reduces manual drafting time with high automation

Cons

- Best performance on modern Windows workstations